In the world of commercial printing, particularly when dealing with printing high volumes, offset printing would be considered the most popular technique. But what is it? In order to understand the principles behind it, we need to first look at the lithographic process.

In lithography, you start off with a metallic plate or stone whose surface is totally smooth. Whatever text or image you want to be printed is initially written/painted/drawn onto the surface with ink (oil-based). It is then fixed onto this surface by using a chemical process. So when you want to print the image or text, you roll oil-based ink on the plate then place a piece of paper on top with little pressure. Since the surface has been separated into hydrophobic (accept ink) and hydrophilic sections (reject ink), only the image shows up on the paper, which is what you want.

Now, with offset printing, instead of directly printing the image from the plate onto paper, it is transferred to a rubber surface first then onto paper. That is why sometimes, this technique is also referred to as offset lithography. The result is a clearer image.

So why is this technique so popular? Probably the biggest reason is associated with economies of scale. As volume increases, the cost of printing per page decreases. A majority of the cost is in the initial preparation. However, with each additional print, you would be generally paying only for the paper and ink, which is relatively small in cost. At the same time, you can still maintain high quality in each printing, which is a huge advantage – consistently clean and sharp images. Another positive factor is that the printing plates can be easily and rapidly produced. On top of that, the plates from this process last longer than the traditional lithographic process since the plates don’t come in direct contact with the paper.

Of course, offset commercial printing is not without its flaws. From a cost perspective, the initial setup of the printing press (briefly mentioned earlier) may represent a deterrent. It wouldn’t recommend that if your printing job is of small quantity to use this method. Also, if the printing plates are not properly and regularly maintained, they can oxidize which leads to negative images being printed.

So basically, if you need a very large amount of printing done, retain high quality in each and every print, plus still be cost-efficient with the entire process, then offset printing is a suitable choice indeed.

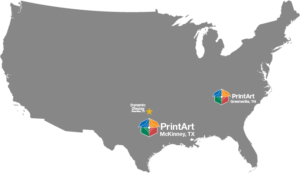

PrintArt – Accurate Die Cutting

413 Interchange St.

McKinney, TX 75071

972.562.7921

https://www.printart-adc.com