You have spent time and money developing your product. A patent has been filed. You have committed financial resources, more than expected, to make your great idea come to life. You have produced a small quantity and now you are ready to take your idea to market. You approach distributors or retailers and they love your product.

Then you get your first order and the realization comes about. How am I going to get my great product to my new customer? How will it be packaged? A customer wants to order a case of your product, how many are in a case? How will my product tell its story on the retail shelf?

These packaging problems and many other surfaces when you finally get your product to market. And in many cases, the packaging costs are the last thing a new product developer thinks of, plus many times the cost is not even in the projected cost.

Now comes the panic…

How do I package my new product for as little as possible? When in reality packaging can be the most important part of your new product. One of my current customers makes replacement transmission kits. One kit design – a standard brown retail box with a small label describing what transmissions it replaces. The other package has a four-color laminated graphic custom box that has all the information about how to install, kit parts, and what transmission it replaces. The interesting thing is although both kits have the exact same components, the kit with the four-color litho-laminated graphic packaging sells for more than the other generic transmission kit and it outsells the plain brown box almost two to one. This is why the old adage “packaging sells” is really true.

For new retail products to sell, a story about the new product must normally be told. In a retail atmosphere, the printed packaging or custom box tells that story. Custom retail packaging has graphics printed on the box, but the design of the package is also important. Maybe your product needs a custom packaging design, a windowed box, or a certain box style will allow for more information to be presented to the prospective buyer.

Now that your product has retail packaging that promotes the product, you have to get it to the retailer safely and in quantities that make sense to you financially and to your customer. Shipping boxes can be made in almost any size and style. Many times you can find a stock shipping box, that will be the right size, from online stock packaging companies, but other times, it requires a custom made shipping box, also called a custom corrugated carton. Package designers are not just for retail packaging, but also for protective packaging.

Some products will require protective packaging along with the shipping cartons. Box Style, corrugated board strength, and the correct cushioning all play a part in safely transporting your product to its destination. A good rule of thumb is a 2″ barrier of protection between your products for protection if they are fragile in nature. Anything from crumpled newspaper and loose-fill peanuts to custom foam packaging can help protect your product during shipment. If you are unsure contact a packaging professional.

Remember, a good retail graphical package design and the properly packed shipping box will help make your products get to market safely and then move off the shelves.

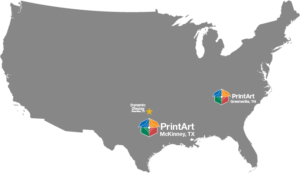

It can be a fairly complex process but don’t feel overwhelmed, reach out to PrintArt today and explain what you need. Their customer service department will put together a cost-effective quote and help your vision come to reality!.

PrintArt – Accurate Die Cutting

413 Interchange St.

McKinney, TX 75071

972.562.7921

https://www.printart-adc.com