If you take a look around, you would know at once that almost all the objects including the tables, chairs, electronics, plastic containers, rubber mats, and fiberboard, etc. are in perfect shape in accordance with their applications. Have you ever wondered how this level of precision in the form of design and pattern is acquired? This process has a very important role to play in this. Apart from materials that we use on a regular basis such as cell phones, plastic cases, and other miscellaneous accessories made of rubber, plastic, glass, etc., these methods also provide proper shape to several high-tech products and industrial components.

What is Die Cutting and how is it done?

It can be defined as a manufacturing process that uses die or specially shaped blades that are bent into the desired shape according to the application. This is required in order to cut materials such as wood, metal, plastic, rubber, fabric, glass, and other materials with precision. The process aims at providing favorable and enticing shapes and designs to the finished products and objects before being sold to the market. On the other hand, several of these products and items are assembled together through a series of steps, which would finally create a finished product.

Besides, in many other cases, machines or devices require to undergo die-cutting before being used further in the process of manufacturing the end product. Hence, several important machined parts and industrial components are die-cut to suit the applicable purposes for which they are produced.

What are various applications and what are the industries served by it?

Reliable and successful service providers are aware of the increasing demands of several industries for precision-cut and accurately-designed parts and accessories for different industrial applications. Hence, they make sure to cater to their clients’ needs accordingly by providing efficient services. Industries related to electronics, appliances, telecommunications, automotive, electrical, and construction constantly require precisely die-cut materials and parts. Die-cutting services hence are used in the following areas of application:

- Abrasives

- Carpets and Flooring

- Cork and Disposables

- Automotive Parts

- Felt

- Metals

- Envelops

- Clothing and Fabric

- Electronics, LCDs, Mobile Phone Coverings and Accessories

- Foam and Sponge

- Filters

- Decorative

- Footwear Components

- Furniture and Seating

- Gasket, Seals and Washers

- Insulation

- Pipes and Tubes

- Leather and Rubber

- Medical products

- Laminates and Composites

- Plastic Cards/Credit Cards

- Textiles

- Tapes

- Paper and Card

- Packaging

- UPVC Doors and Panels

- Protective Clothing, and so on

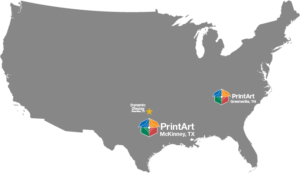

It can be a fairly complex process but don’t feel overwhelmed, reach out to PrintArt today, and explain your needs. Their customer service department will put together a cost-effective quote and help your vision come to reality!

PrintArt – Accurate Die Cutting

413 Interchange St.

McKinney, TX 75071

972.562.7921

https://www.printart-adc.com